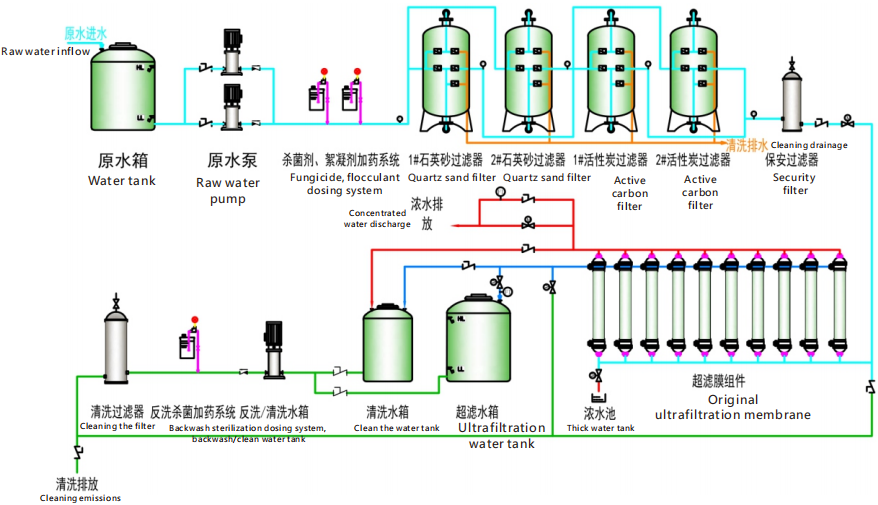

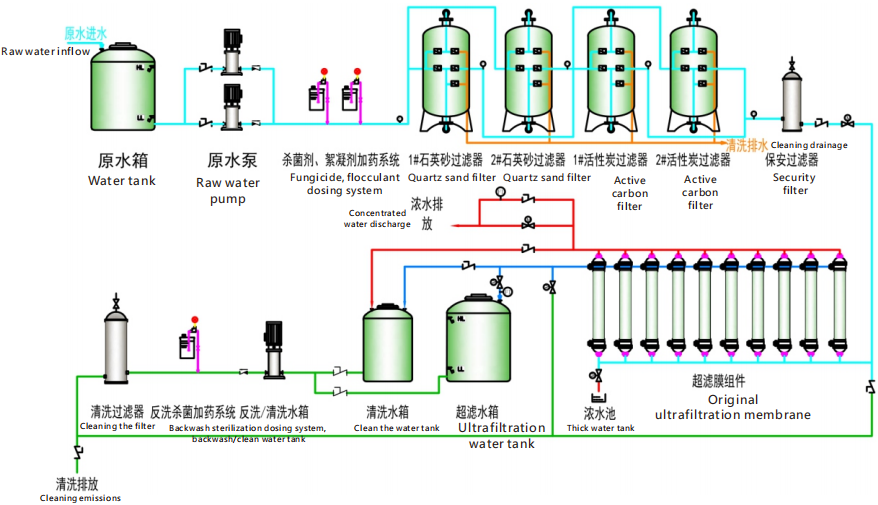

Ultrafiltration water treatment equipment from Ticktock is a process driven by pressure.Through the micropore screening on the membrane surface, particles and impurities with a diameter of 0.002-0. 1μm can be intercepted, which can effectively remove colloids, silicon, proteins, and microorganisms in the water. And organic matter. When the liquid mixture flows through the surface of the membrane under a certain pressure, the solvent and small molecular substances penetrate the membrane and are trapped, thereby achieving size and intermolecular separation and purification. It can be widely used in the separation, concentration and purification of substances. The process has no phase transformation, no heating, normal temperature operation, energy saving, and particularly suitable for the separation of heat-sensitive substances. The ultrafiltration process is simple, with few supporting devices, simple operation and low maintenance cost. Resistant to chemical erosion, wide range of PH adaptability, largest membrane area per unit volume, lowest investment cost, simplecleaning.

Application fields of Ticktock ultrafiltration equipment:

◆Mineral water: In the manufacture of mineral water, ultrafiltration technology is applied. In the engineering design, the pore size and membrane type of the membrane will be selected based on the water quality analysis report of the mineral water source, and the ultrafiltration design will be designed.

◆Food: Ultrafiltration technology is gradually adopted in the production of dairy products, juice, wine, condiments and other foods, such as the separation of protein and low molecular weight lactose in milk or whey from water, the clarification and sterilization of fruit juice, and the separation of colored wines The removal of proteins, polysaccharides and other colloidal impurities, and the removal of bacteria in soy sauce and vinegar show the advantages of economy, reliability and quality assurance compared with traditional methods.

◆Medicine: In the production of medicine and biochemical industry, it is often necessary to separate and purify heat-sensitive substances, and ultrafiltration technology shows its outstanding advantages in this regard. Using ultrafiltration to separate and concentrate biologically active substances (such as enzymes, viruses, nucleic acids, special proteins, etc.) is quite suitable for drugs extracted from animals and plants (such as alkaloids, hormones, etc.). The extracts often contain macromolecules or Solid matter can be separated by ultrafiltration in many cases, so that the product quality can be improved.

◆Pure water, ultrapure water: primary purification of industrial water, RO pretreatment for preparation of ultrapure water from pure water, terminal treatment of pure water and ultrapure water.

◆Environmental protection: Advanced treatment of industrial wastewater, urban reclaimed water reuse system, recovery of electrophoretic paint and oil products.

◆Fermentation: Separation and refinement of biochemical fermentation broth, concentration and refinement of enzymes, clarification and filtration of sugar and xylitol.

Application fields of Ticktock ultrafiltration equipment:

◆Mineral water: In the manufacture of mineral water, ultrafiltration technology is applied. In the engineering design, the pore size and membrane type of the membrane will be selected based on the water quality analysis report of the mineral water source, and the ultrafiltration design will be designed.

◆Food: Ultrafiltration technology is gradually adopted in the production of dairy products, juice, wine, condiments and other foods, such as the separation of protein and low molecular weight lactose in milk or whey from water, the clarification and sterilization of fruit juice, and the separation of colored wines The removal of proteins, polysaccharides and other colloidal impurities, and the removal of bacteria in soy sauce and vinegar show the advantages of economy, reliability and quality assurance compared with traditional methods.

◆Medicine: In the production of medicine and biochemical industry, it is often necessary to separate and purify heat-sensitive substances, and ultrafiltration technology shows its outstanding advantages in this regard. Using ultrafiltration to separate and concentrate biologically active substances (such as enzymes, viruses, nucleic acids, special proteins, etc.) is quite suitable for drugs extracted from animals and plants (such as alkaloids, hormones, etc.). The extracts often contain macromolecules or Solid matter can be separated by ultrafiltration in many cases, so that the product quality can be improved.

◆Pure water, ultrapure water: primary purification of industrial water, RO pretreatment for preparation of ultrapure water from pure water, terminal treatment of pure water and ultrapure water.

◆Environmental protection: Advanced treatment of industrial wastewater, urban reclaimed water reuse system, recovery of electrophoretic paint and oil products.

◆Fermentation: Separation and refinement of biochemical fermentation broth, concentration and refinement of enzymes, clarification and filtration of sugar and xylitol.Ultrafiltration water treatment equipment from Ticktock is a process driven by pressure.Through the micropore screening on the membrane surface, particles and impurities with a diameter of 0.002-0. 1μm can be intercepted, which can effectively remove colloids, silicon, proteins, and microorganisms in the water. And organic matter. When the liquid mixture flows through the surface of the membrane under a certain pressure, the solvent and small molecular substances penetrate the membrane and are trapped, thereby achieving size and intermolecular separation and purification. It can be widely used in the separation, concentration and purification of substances. The process has no phase transformation, no heating, normal temperature operation, energy saving, and particularly suitable for the separation of heat-sensitive substances. The ultrafiltration process is simple, with few supporting devices, simple operation and low maintenance cost. Resistant to chemical erosion, wide range of PH adaptability, largest membrane area per unit volume, lowest investment cost, simplecleaning.

Application fields of Ticktock ultrafiltration equipment:

◆Mineral water: In the manufacture of mineral water, ultrafiltration technology is applied. In the engineering design, the pore size and membrane type of the membrane will be selected based on the water quality analysis report of the mineral water source, and the ultrafiltration design will be designed.

◆Food: Ultrafiltration technology is gradually adopted in the production of dairy products, juice, wine, condiments and other foods, such as the separation of protein and low molecular weight lactose in milk or whey from water, the clarification and sterilization of fruit juice, and the separation of colored wines The removal of proteins, polysaccharides and other colloidal impurities, and the removal of bacteria in soy sauce and vinegar show the advantages of economy, reliability and quality assurance compared with traditional methods.

◆Medicine: In the production of medicine and biochemical industry, it is often necessary to separate and purify heat-sensitive substances, and ultrafiltration technology shows its outstanding advantages in this regard. Using ultrafiltration to separate and concentrate biologically active substances (such as enzymes, viruses, nucleic acids, special proteins, etc.) is quite suitable for drugs extracted from animals and plants (such as alkaloids, hormones, etc.). The extracts often contain macromolecules or Solid matter can be separated by ultrafiltration in many cases, so that the product quality can be improved.

◆Pure water, ultrapure water: primary purification of industrial water, RO pretreatment for preparation of ultrapure water from pure water, terminal treatment of pure water and ultrapure water.

◆Environmental protection: Advanced treatment of industrial wastewater, urban reclaimed water reuse system, recovery of electrophoretic paint and oil products.

◆Fermentation: Separation and refinement of biochemical fermentation broth, concentration and refinement of enzymes, clarification and filtration of sugar and xylitol.

Application fields of Ticktock ultrafiltration equipment:

◆Mineral water: In the manufacture of mineral water, ultrafiltration technology is applied. In the engineering design, the pore size and membrane type of the membrane will be selected based on the water quality analysis report of the mineral water source, and the ultrafiltration design will be designed.

◆Food: Ultrafiltration technology is gradually adopted in the production of dairy products, juice, wine, condiments and other foods, such as the separation of protein and low molecular weight lactose in milk or whey from water, the clarification and sterilization of fruit juice, and the separation of colored wines The removal of proteins, polysaccharides and other colloidal impurities, and the removal of bacteria in soy sauce and vinegar show the advantages of economy, reliability and quality assurance compared with traditional methods.

◆Medicine: In the production of medicine and biochemical industry, it is often necessary to separate and purify heat-sensitive substances, and ultrafiltration technology shows its outstanding advantages in this regard. Using ultrafiltration to separate and concentrate biologically active substances (such as enzymes, viruses, nucleic acids, special proteins, etc.) is quite suitable for drugs extracted from animals and plants (such as alkaloids, hormones, etc.). The extracts often contain macromolecules or Solid matter can be separated by ultrafiltration in many cases, so that the product quality can be improved.

◆Pure water, ultrapure water: primary purification of industrial water, RO pretreatment for preparation of ultrapure water from pure water, terminal treatment of pure water and ultrapure water.

◆Environmental protection: Advanced treatment of industrial wastewater, urban reclaimed water reuse system, recovery of electrophoretic paint and oil products.

◆Fermentation: Separation and refinement of biochemical fermentation broth, concentration and refinement of enzymes, clarification and filtration of sugar and xylitol.

We are a professional water treatment company dedicated to providing high-quality water treatment solutions to customers worldwide. We have years of industry experience and professional knowledge, as well as a wide supply chain network, to provide comprehensive services to customers.

Weclome to visit us!

We are a professional water treatment company dedicated to providing high-quality water treatment solutions to customers worldwide. We have years of industry experience and professional knowledge, as well as a wide supply chain network, to provide comprehensive services to customers.