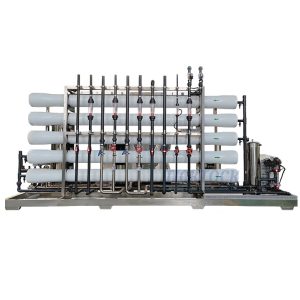

50 Tons/Hour Single-Stage Reverse Osmosis Equipment

(Technical Introduction and Application Overview)

I. Product Overview

The 50-ton/hour single-stage reverse osmosis (RO) system is a cutting-edge water purification solution designed for large-scale

industrial and commercial applications. Utilizing advanced reverse osmosis membrane technology, it effectively removes dissolved

salts, organic contaminants, heavy metals, bacteria, and viruses from raw water sources such as groundwater, tap water,

or surface water . With a maximum salt rejection rate of 98-99% and an operational pressure range of 1.3–1.8 MPa, this system

ensures stable production of high-purity water (conductivity ≤10 μS/cm), meeting stringent standards for industries like

electronics, pharmaceuticals, and food processing .

II. Core Technology & Working Principle

Reverse Osmosis Mechanism

The system employs semi-permeable RO membranes with pore sizes as small as 1/10,000 μm (1 nm), capable of filtering particles 1/6,000

the size of E. coli and 1/300 the size of viruses . By applying hydraulic pressure exceeding the osmotic pressure of saline water,

water molecules permeate through the membrane, while contaminants are concentrated and discharged as brine . This process operates

without phase change, ensuring energy efficiency and environmental safety .

Key Components

Pretreatment System: Includes multi-media filters (quartz sand), activated carbon filters, and precision filters (5 μm) to remove

suspended solids, colloids, chlorine, and organic matter, protecting downstream RO membranes .

High-Pressure Pump: Provides the necessary pressure (typically 1.5–2.5 MPa) to drive water through RO membranes .

RO Membrane Modules: Configured with 50–54 high-performance polyamide composite membranes (e.g., Dow Filmtec BW30-400) arranged in a

6:3 pressure vessel layout for optimal flow distribution .

Automated Control: PLC-based systems enable real-time monitoring of pressure, flow, and water quality, with automatic alarms and

shutdowns for abnormal conditions .

III. System Specifications

Capacity: 50 m³/h (12,000 GPD) of purified water output .

Power Supply: 380V/50Hz or 220V/50Hz, adaptable to global standards .

Water Recovery Rate: Up to 75%, minimizing wastewater generation .

Installation Requirements:

Ambient temperature: 5–45°C

Floor space: ≥5m height, load-bearing flooring, and drainage facilities .

Optional Add-ons: UV sterilizers, ozone generators, or mixed-bed polishers for ultrapure water applications .

IV. Process Flow

The standardized treatment sequence ensures consistent performance:

Raw Water Storage: Balances supply fluctuations via buffer tanks .

Pretreatment:

Multi-media filtration (removes particles >20 μm)

Activated carbon adsorption (eliminates odors, residual chlorine, and organic matter)

Scale inhibitor dosing (prevents CaCO₃/MgSO₄ scaling on membranes) .

RO Core Process: High-pressure separation produces purified water and concentrated brine .

Post-Treatment: Optional disinfection or polishing for specialized needs .

V. Industry Applications

Electronics & Semiconductors: Produces ultrapure water for wafer cleaning, circuit board manufacturing, and microchip production .

Pharmaceuticals: Meets USP/EP standards for injectable water and medical device rinsing .

Food & Beverage: Ensures compliance with hygiene standards for bottling, brewing, and ingredient processing .

Power Generation: Supplies low-conductivity water for boiler feed and cooling systems .

Environmental Solutions: Treats wastewater for reuse in textiles, printing, and landfill leachate management .

VI. Advantages

Energy Efficiency: 15–30% lower energy consumption compared to multi-stage systems .

Low Maintenance: Automated CIP (clean-in-place) cycles extend membrane lifespan to 3–5 years .

Scalability: Modular design allows capacity expansion by adding membrane units .

Compliance: Aligns with ISO 9001, CE, and NSF/ANSI certifications for quality assurance .

VII. Technical Support

Our company provides turnkey services, including site assessment, customized engineering, and 24/7 remote monitoring. With a global

network of service centers, we guarantee prompt maintenance and spare parts supply .

Conclusion

The 50-ton/hour single-stage RO system represents a cost-effective, reliable solution for industries demanding high-volume purified

water. Its robust performance, coupled with low operational costs, positions it as a cornerstone technology for sustainable water

management worldwide.

https://www.youtube.com/@ticktockwater

50 Tons/Hour Single-Stage Reverse Osmosis Equipment